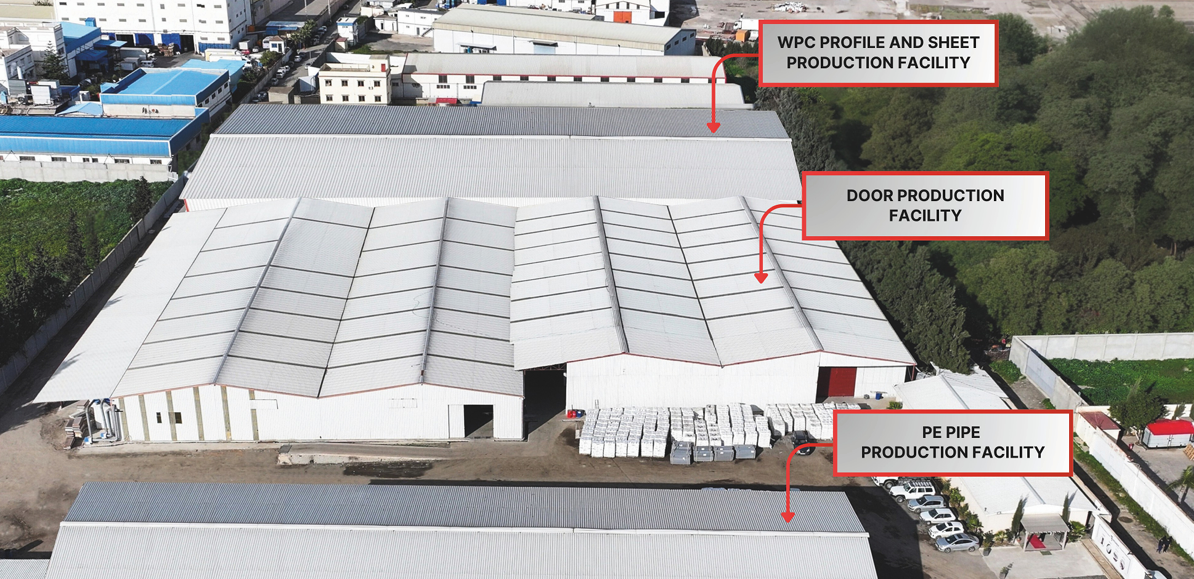

WPC (Wood Plastic Composite) Profil ve Levha Üretim Tesisi

Cezayir WPC profil üretim tesisi, Erdoor ve Decker markalı ürünlerin profil ve levhalarını üretmektedir. Tesiste bulunan 12 ekstrüder hattıyla aylık 750 ton WPC profil ve 250 ton PVC levha üretimi gerçekleştirilmektedir. Bu ürünler, kapı sektörü başta olmak üzere birçok sektörde yarı mamul girdi olarak kullanılmaktadır. Üretilen ürünlerin büyük çoğunluğu Cezayir’de lokal pazara sunulurken, aynı zamanda Cezayir’e komşu ülkelerde de satılmaktadır. Decker markası altında ise, ahşap ve plastiğin birleşimiyle oluşan kompozit zemin döşeme malzemeleri üretilmekte olup, bu ürünler park, bahçe, teras ve havuz kenarı gibi dış mekan uygulamaları için dünya pazarına sunulmaktadır.

Kapı Üretim Tesisi

Profil tesisimizden tedarik ettiğimiz profil ve levhalarla, tam otomatik üretim hattımızda el değmeden yeni nesil, doğa dostu kompozit iç oda kapıları üretiyoruz. Tesisimizde yer alan iki adet Melamin pres sayesinde, tek vardiyada 4000 adet kapı yüzeyi ve günlük 2000 adet hazır kapı üretimi gerçekleştirilebilmektedir. Bu kapılar, Cezayir pazarı dışındaki Afrika Birliği üyesi tüm ülkelere ihraç edilmektedir.

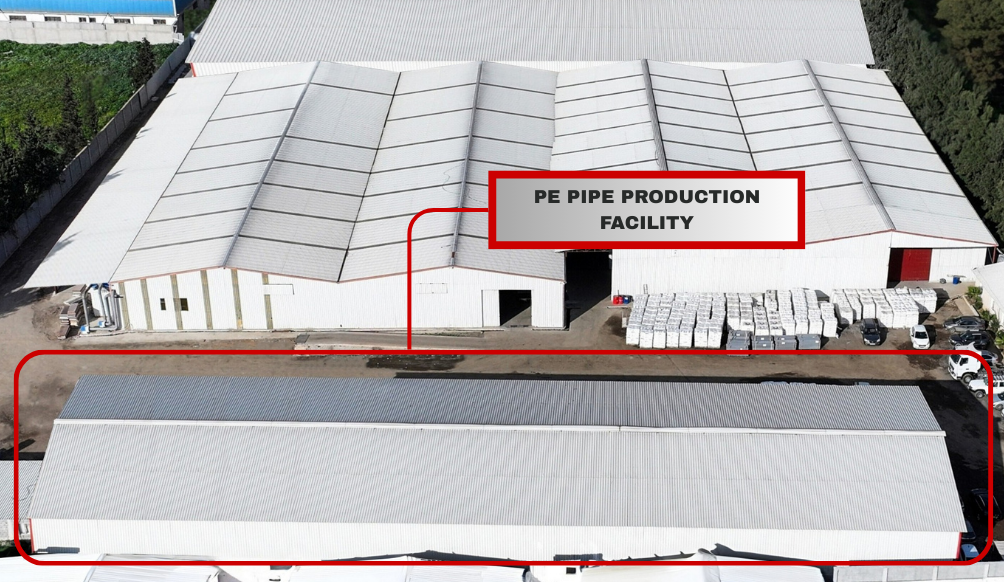

PE Boru Üretim Tesisi

Kuzey Afrika pazarında hızla gelişen tarım sektörüne yönelik olarak kurulmuştur. Bu tesiste, tarıma hitap eden PE yağmurlama boruları, yuvarlak ve yassı damla sulama boruları ile ilgili ek parçalar üretilmektedir. Üretimde kullanılan hammaddeler, kendi PE geri dönüşüm tesisimizden temin edilmekte olup, sürdürülebilir üretim süreçleriyle yüksek kalite standartlarında borular elde edilmektedir. Ürünlerimiz, yüksek dayanıklılık ve verimlilik sağlamak amacıyla özel olarak işlenmektedir.

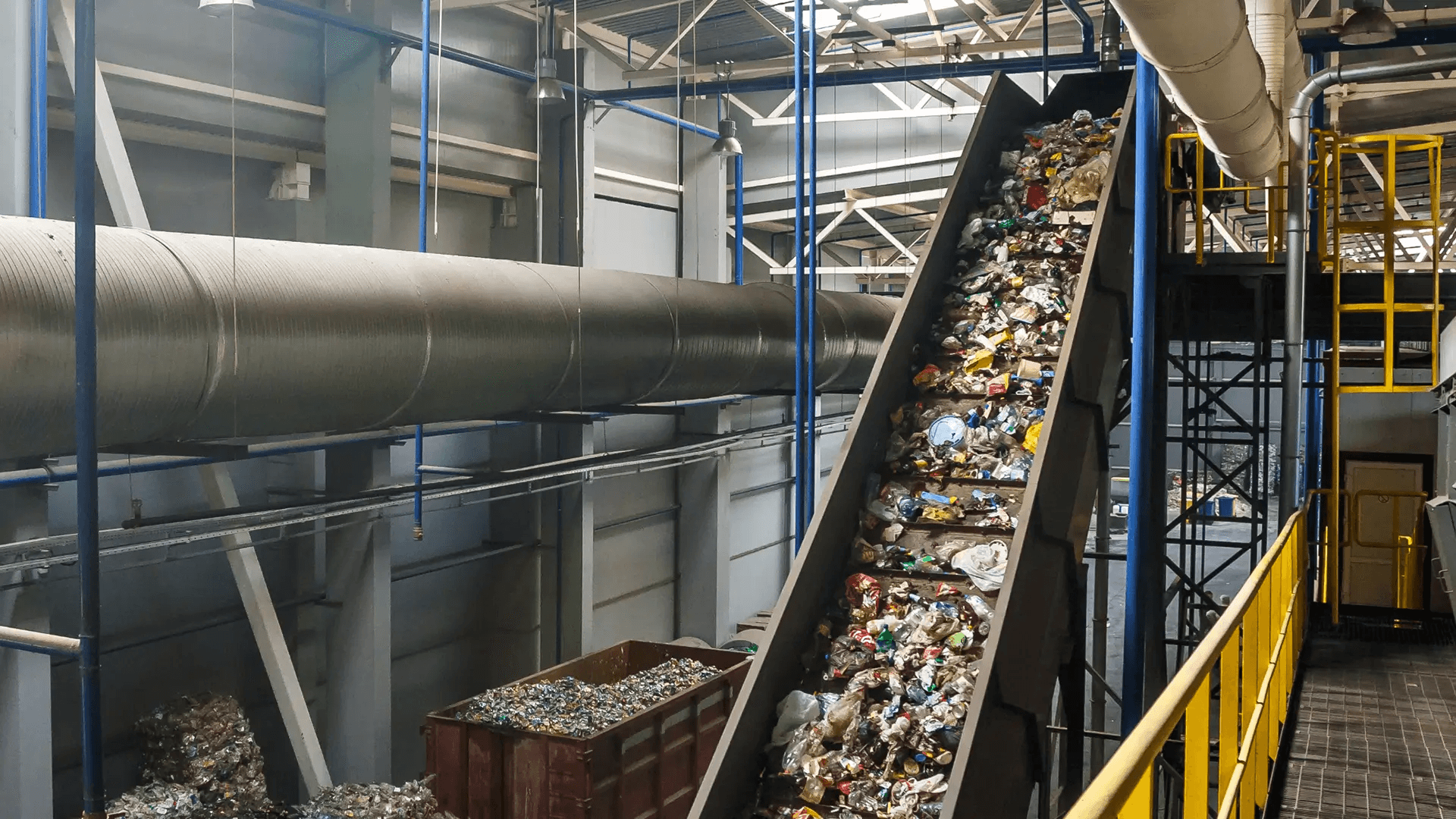

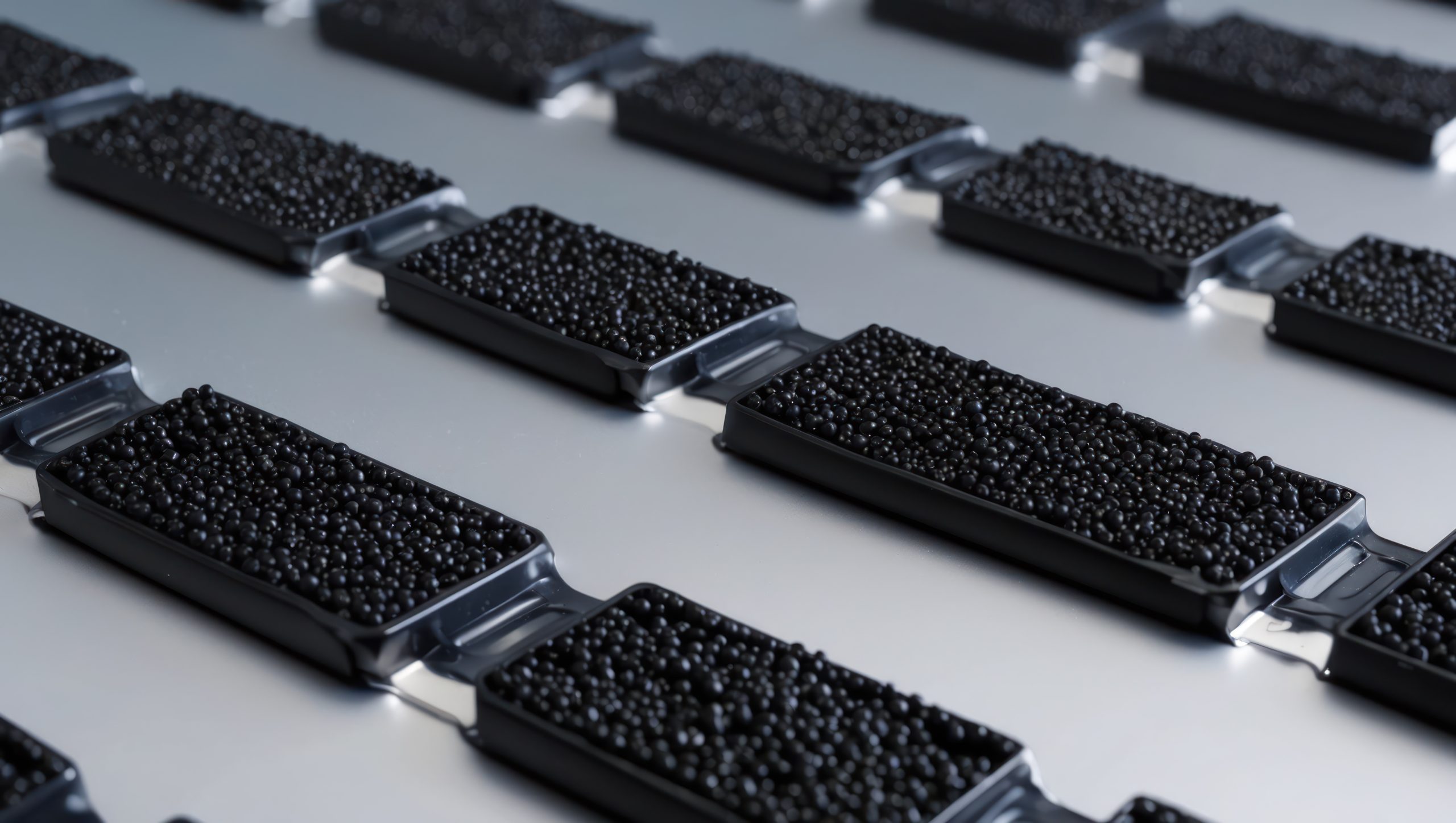

PE/PP Geri Dönüşüm Tesisi

Cezayir iç piyasasından temin edilen ambalaj atıkları, ayrıştırma, temizleme ve işleme süreçlerinden geçirilerek yüksek kaliteli geri dönüştürülmüş granüllere dönüştürülmektedir. Elde edilen granüller, boru ve poşet üretimi yapan firmalara hammadde olarak satılmaktadır.